In April 2016, Mr. Bruce Capuano, Vice President of Spectral Systems, LLC, engaged MTEC to solve issues with the company’s product rejection rates. MTEC Senior Project Engineer, Phil vanOss stepped in to help with Lean Six Sigma and 5S implementation.

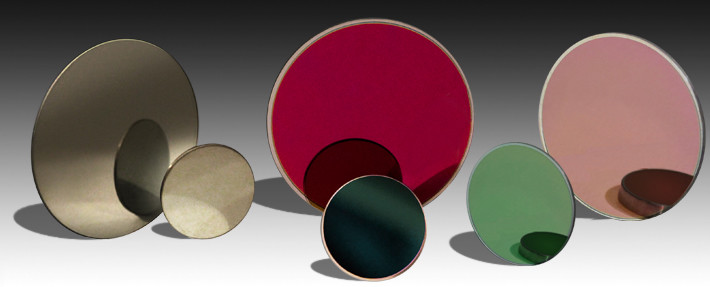

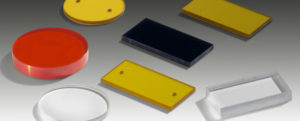

Spectral Systems, a leader in precise optical components, coatings and systems integration, was founded over 30 years ago. The company prides itself on the ability to make optics to specification for each and every customer. Located in Hopewell Junction, NY with 45 employees, Spectral houses state of the art polishing, coating and inspection equipment. Spectral provides the most comprehensive capabilities in optical solutions for the entire infrared range, from the vacuum UV to the Far-IR.

The ultimate goal of the project was to improve Spectral’s internal systems,  specifically when it came to production of their lenses. The company was looking to standardize their operating procedure and equipment as well as their methods and processing. By improving these aspects of the company, better product flow was expected as the first pass quality of their lenses improved.

specifically when it came to production of their lenses. The company was looking to standardize their operating procedure and equipment as well as their methods and processing. By improving these aspects of the company, better product flow was expected as the first pass quality of their lenses improved.

Spectral Systems and MTEC worked to reduce lens fogging and the corresponding rejection rates caused by this fogging. Decreasing rejection rates would allow the company to perform more efficiently and enhance the overall quality of the lens they were producing. Phil vanOss integrated himself into Spectral’s team in order to inform the team about Lean 6 Sigma and how to define, measure, analyze, improve, and control within the company. The training sessions included Process Flow Analysis as well as Data Display and Root Cause Analysis.

By updating detailed standardized operating procedures, the company was able to take their rejection rate from 300 per week to 50 per week (4 week average) per ‘Run Chart’ analysis. As the implementation continues within the company, there is an expected continued downward trend in clouding rejects to about 20 per week. In addition, the company processed jobs 10 times faster than before which helps coating to stay on target. During the week of November 12, the company even achieved their goal of zero reworks.

States VanOss, “Altogether, the partnership focused on teaching a problem solving approach which will extend greatly beyond the project itself. This way of thinking is an invaluable asset for Spectral as they continue to grow and optimize their internal functions.”

States VanOss, “Altogether, the partnership focused on teaching a problem solving approach which will extend greatly beyond the project itself. This way of thinking is an invaluable asset for Spectral as they continue to grow and optimize their internal functions.”

As part of their efforts to improve internal systems, Spectral also worked with MTEC to implement Lean 5S Visual Systems Training, a system for detailing and improving the flow of materials within the company. This was completed by organizing and cleaning some of Spectral’s facility. It also included the removal of excess materials and organizing a storage room, therefore increasing productivity and cleanliness of the facility.

States Mr. Capuano, “We, at Spectral Systems, are very pleased with the outcome of this project and plan on using MTEC for future training and manufacturing improvement projects”.