What is a Supply Chain?

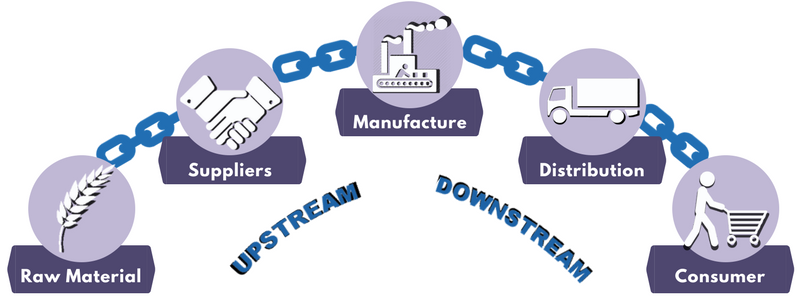

Supply chains consist of all the steps involved in getting a product from a raw material into the hands of the customer. Typically, the supply chain begins with the vendors or suppliers. These are the businesses that provide raw materials. Next in the supply chain is manufacturing. This is the process of converting the raw materials into products that are ready to sell. The final step is distribution which can involve multiple different intermediaries. Some of these middle-men could be wholesalers, retailers, distributors, and even the internet.

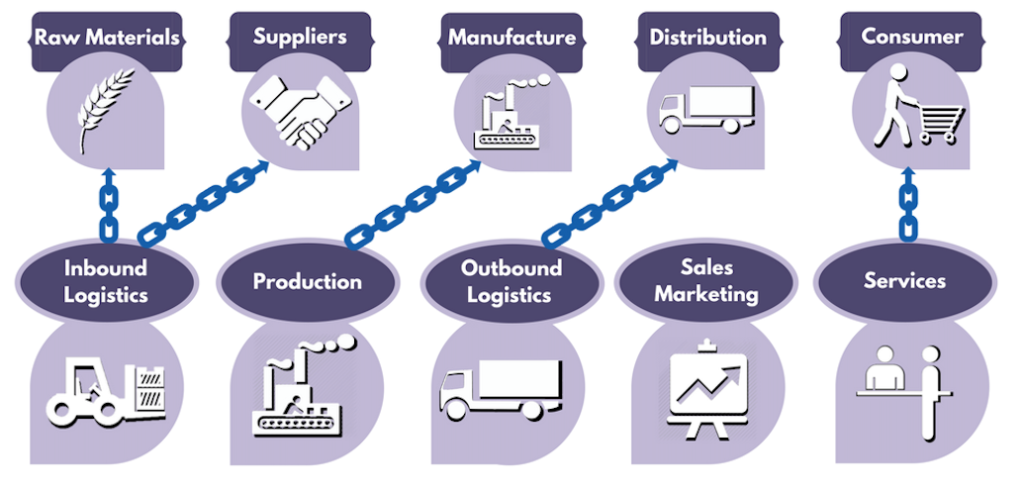

Often, different stages within the supply chain are referred to as upstream or downstream. Upstream operations are those in which the materials flow into the organization. Downstream operations are those in which materials (mostly in the form of finished products) flow away from the organization to the customers. Similarly, the term logistics is used when talking about a business’s supply chain. Inbound logistics are related to the upstream activities and include all of the movement of the product before manufacturing. They involve receiving materials, storing them, and the manufacturing processes required to produce the product. Of course, outbound logistics are related to the downstream operations involving just about all of the movement of the product once it is a finished good.

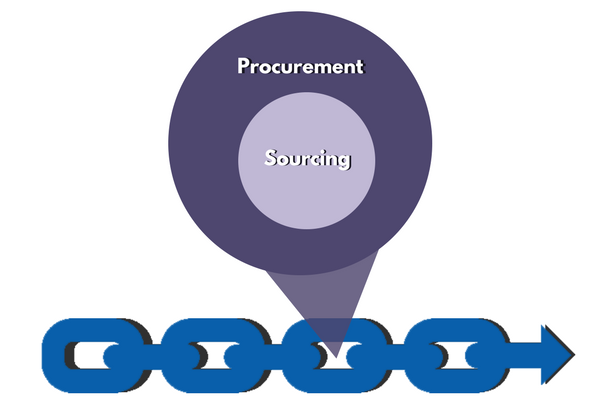

While we’re on the subject of words often associated with supply chain, what about procurement and sourcing? These two terms are usually used interchangeably with supply chain when in fact, they each refer to a slightly different responsibility involved in a supply chains. You can think of sourcing as part of the procurement process, while together they are part of a supply chain. The goal of sourcing is to locate evaluate various suppliers for products. Research and negotiation are a normal part of this process because the profitability of a business can rely heavily on the cost of materials. Procurement involves finding products (sourcing), but also developing quality standards for the materials. It also involves purchasing the correct quantities in a timely order to maintain the proper flow of materials.

So why is a supply chain important? Businesses must have a supply chain strategy that corresponds with their business strategy. Depending on how a business decides to compete with the market, their supply chain is what will ultimately support that decision. The supply chain is made up of different processes that work to create a product, these processes lay the groundwork for where a company decides to add value. The value chain is what gives a business a competitive advantage over others. The more value that is created, the more a customer will want a product, and therefore, the more profit a company will make.

There are many opportunities within the supply chain to add value for the customer. Michael E. Porter, author of Competitive Advantage, identifies different ways in which businesses are able to gain a competitive advantage. The different strategies rely on adding customer value within different steps of the value chain. He defines the activities of the value chain to include, inbound logistics, operations, outbound logistics, marketing and sales, and service. We already know that inbound logistics and outbound logistics are part of what we defined as the supply chain. Operations are more or less another term for manufacturing as they are all the activities involved in turning raw materials into a product.

The idea is that a competitive advantage is created when value is added more effectively than the competition to any of these steps. The customer value added exceed the cost of these activities which will then create a profit for the company. For example, Walmart and Ikea are companies who implement low cost strategies, focusing on supplying their customers with the lowest possible prices in the market. By positioning themselves this way they may have to focus on finding suppliers with materials at a lower cost than their competition. They may have to make decisions regarding outsourcing or making operations more efficient.

All of these important decisions define the position a company takes to become profitable. These decisions are changes that need to be made to the activities involved in a company’s supply chain. The supply chain is the framework for the value chain, which is the essential reason a customer will choose your product over the competitions’.

At MTEC, our team specializes in analyzing supply chains to identify areas of opportunity. Through our network of professionals we are able to develop recommendations on how to improve and optimize processes. We establish partnerships with companies and external resources while ensuring intellectual property protection to help your business reduce costs, add value, and work to achieve high standards.

If you are interested in taking a closer look at your supply chain, or just have questions regarding our services, call us at 845-391-8214 or contact us here.