By Daniel Timoldi

Many of us know that automation is a great way to help increase efficiency in your manufacturing processes. However, not everyone can afford state-of-the-art machinery or robotics. When it comes to inexpensive automation machines, there are several options available that can help streamline manufacturing processes without breaking the bank. By automating tasks, small businesses can free up their employees to focus on more strategic and creative work. This can lead to increased productivity, improved customer service, and a stronger bottom line. Here are a few affordable options to consider when introducing automation to your processes:

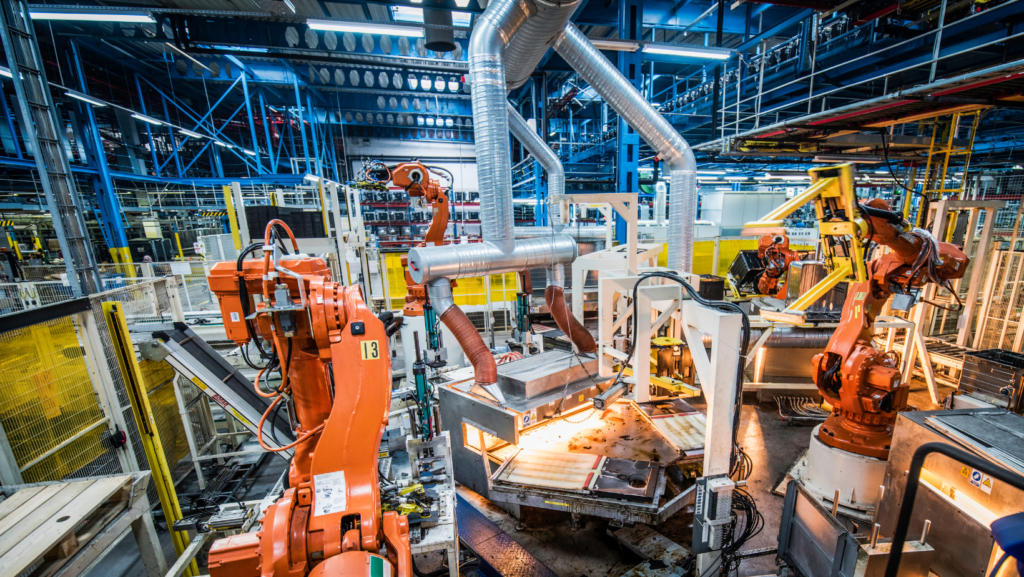

Collaborative Robots (Cobots)

Cobots are designed to work alongside humans, and they are often more affordable than traditional industrial robots. They can perform tasks such as assembly, pick and place, and machine tending. Cobots are known for their ease of programming and flexibility, making them a cost-effective option for small and medium-sized enterprises. By reducing strain on your employees, you can increase their stamina and reduce the risk of injury.

Programmable Logic Controllers (PLCs)

PLCs are specialized computers used to control and automate machinery and processes. They are widely used in manufacturing to control tasks such as machine operation, monitoring sensors, and managing inputs and outputs. PLCs are relatively affordable and can be programmed to perform a wide range of automation tasks.

Conveyor Systems

Conveyor systems are widely used in manufacturing to transport materials and products within a facility. They can be automated to optimize the movement of goods and materials, reducing manual labor and improving efficiency. Conveyor systems come in various sizes and configurations, making them suitable for different manufacturing setups.

Automated Guided Vehicles (AGVs)

AGVs are autonomous vehicles used to transport materials within a manufacturing facility. They can navigate predefined paths, avoiding obstacles, and can be programmed to perform tasks like material handling, goods transportation, and inventory management. AGVs come in different forms, from simple carts to more advanced robotic vehicles.

3D Printers

3D printers have become increasingly more affordable and offer automation capabilities for prototyping and small-scale production. They can produce complex designs and functional parts directly from digital models, reducing the need for manual labor and more traditional manufacturing processes.

Barcode and RFID Systems

Barcode and RFID (Radio Frequency Identification) systems automate data collection and tracking processes. They can be used for inventory management, product identification, and tracking throughout the manufacturing process. These systems are relatively inexpensive and can integrate with existing manufacturing infrastructure.

Automated Packing Machines

Automated packing machines can streamline the packaging process by automatically sealing, labeling, and sorting products. They are designed to handle various packaging materials and can significantly increase packaging efficiency and consistency.

When considering inexpensive automation machines, it’s important to assess the specific needs and requirements of your manufacturing process, because automation isn’t one-size-fits-all. Look for machines that offer the functionalities you require at a cost that fits your budget. Additionally, consider the scalability and ease of integration with existing systems to ensure a smooth implementation. Your employees will thank you later!

Are you thinking of introducing methods of automation to your manufacturing processes? MTEC’s highly skilled team of engineers can optimize your current manufacturing equipment, or even build custom automation solutions for your products. Contact us today to find out more or reach MTEC’s Business Development Specialist, Dan Timoldi, by phone at (845)391-8214 Ext. 3004 or via email at dan.timoldi@hvtdc.org.