No matter how innovative and in-demand your product is, if your manufacturing processes and factory layout are not optimized, your company has waste that is causing you to miss out on valuable sales opportunities. This was the case for REELEX Packaging Solutions, until together with MTEC they nailed down fruitful solutions.

REELEX Packaging Solutions Inc. is a wire and cable packaging manufacturer located in Patterson, NY. The company’s innovative packaging solution for wire is more eco-friendly, cost-effective, and efficient than its traditional competitors, the spool and reel. Behind the magic of these products are REELEX Machines, which are also designed, manufactured, and distributed by REELEX Packaging Solutions Inc. The machines range in capacity and are designed to be used by fellow wire and cable manufacturing facilities.

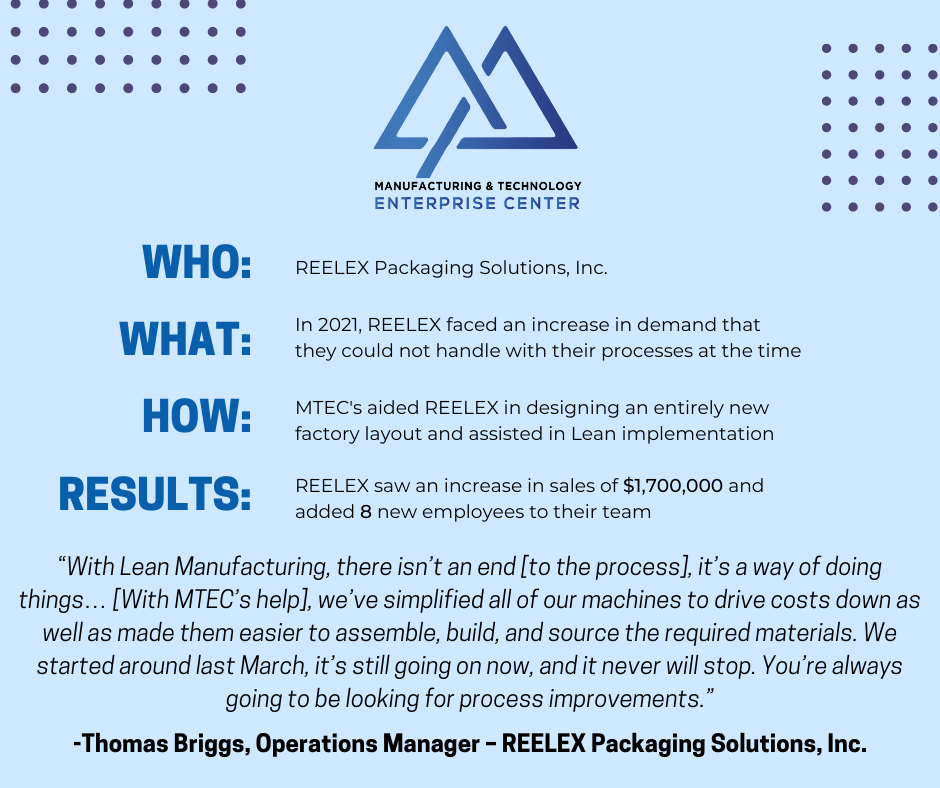

REELEX Packaging Solutions Inc. found itself on an upward trajectory in Spring of 2021 due to an increase in demand for the patented REELEX Machines. MTEC realized the best course of action would be to utilize the benefits of Value Stream Mapping to guide effective practices and processes for future demand, market entry, and product evolution. REELEX was then able to redesign their product to become more efficient. Since then, four new products have been developed with the product from the new lean manufacturing process used as the basis of their design. However, they knew there was still room for more growth.

MTEC visited the REELEX site and collaborated with REELEX to provide a more effective factory layout that would work for their team and their needs. MTEC then followed up with monthly check-ins to make continued strategic recommendations as the team continued to work and grow. MTEC’s guidance has helped with everything from introducing a two-bin inventory system to decreasing the amount of tools in each engineer’s toolbox to include only precisely what will be needed on the floor. Through their partnership, MTEC has allowed REELEX to become more effective in their actions and decrease costs.

While introducing new processes can make valuable changes in how your company operates, it’s imperative that all employees are on board, understand the changes made within the company, and understand why they are necessary. Through a workshop involving Lego, MTEC allowed REELEX employees to gain a better understanding of material flow that could then be applied to their positions. This hands-on workshop illustrated why a change in factory layout was necessary for the success of the company and its employees.

MTEC has aided REELEX to scale to higher volumes of production and helped them become ready for fluctuations in demand. REELEX’s Operations Manager, Thomas Briggs, understands that Lean is not a one-and-done, but a process that continues on in perpetuity. When speaking on REELEX’s work with MTEC on Lean implementation, Briggs says, “we started around last March, it’s still going on now, and it never will stop. You’re always going to be looking for process improvements.”

MTEC takes great pride in aiding companies in the Hudson Valley realize their potential. If you need help assessing your operations and improving your manufacturing processes, reach out to us today! To set up a complimentary visit to discuss in further detail, please call our Director of Administration, Phyllis Levine, at (845)391-8214 Ext. 3001 or via email to phyllis.levine@hvtdc.org.