As we’ve discussed in previous blogs, being a food manufacturer is a delicate balancing act. There are so many moving parts to keep up with. Whether it’s safety, inspections, or certifications; it seems as though there is always a new task arising. Food manufacturing also brings with it the responsibility of protecting public health and the safety of your customers. No matter how excellent of a job you may be doing, there is always room for improvement. This is why Catsmo Artisan Smokehouse turned to MTEC to aid with gap analysis and follow-up coaching.

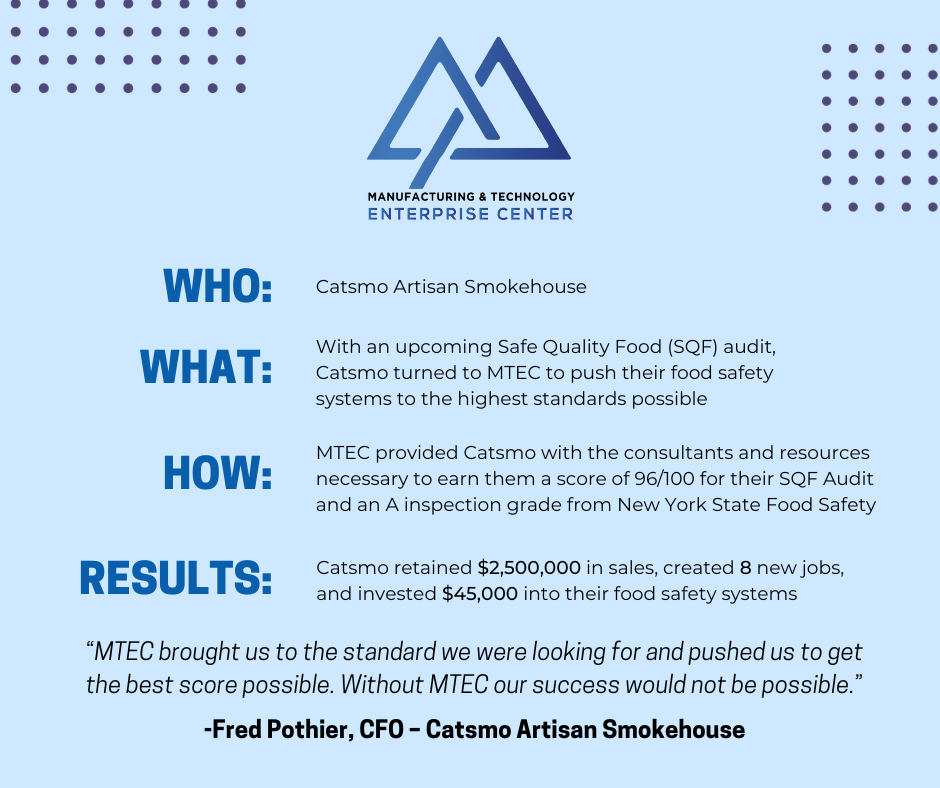

Catsmo Artisan Smokehouse out of Wallkill, NY produces smoked salmon, artisanal cheeses, and premium caviar. Nestled on a hillside just past the Village of Wallkill, Catsmo runs made-to-order production in order to get the freshest product to their clients. In conjunction with Solex Fine Foods, they have upheld their artisanal practices even through a period of substantial growth. Fresh fish is flown in daily from the icy Atlantic waters and is individually inspected by sight and smell before beginning the production process. Working exclusively with fresh and never frozen fish makes Catsmo an incredibly unique food manufacturer, all the more reason that food safety is paramount. In 2020, Catsmo sought MTEC’s assistance and secured a food safety specialist that defined new procedures and was the foundation of their new Food Safety and Quality standards as it is today.

In 2021, Catsmo sought MTEC’s assistance in performing a gap analysis in order to find areas for improvement and ensure they were operating to the highest standards. In collaboration with the Bonney Ziegler Group, MTEC aided Catsmo in identifying opportunities to strengthen their systems and processes. To further improve Catsmo’s food safety systems, Hazard Analysis Critical Control Point (HACCP) was introduced. Through HACCP, Catsmo was able to guarantee that they practiced the utmost care in all aspects of their food safety operations. After the initial inspections, monthly meetings were held to keep Catsmo on a path of continuous improvement.

Over the years, Catsmo has introduced more thorough documentation methods to aid in accountability and the formation of positive habits. They have hired additional full-time staff dedicated to Food Safety and Quality Control. An FDA approved lab was established on site for testing both product and the environment for bacteria. A pre-operations inspection now takes place every day as a prerequisite for their sanitation program to verify compliance to their safety standards and document any deviation. This includes visual, microbial testing, and full documentation before production starts.

Catsmo has also advanced their facilities through renovations and highly organized storage systems. They have enforced more rigorous training for their employees to ensure superior food safety practices across their team. Through their collaboration with MTEC and the Bonney Ziegler Group, Catsmo has achieved excellent standing with Safe Quality Food Institute (SQF) and achieved a score of 96/100 on their most recent SQF audit. In addition, the Catsmo now has members of their team who are trained Preventive Controls Qualified Individuals (PCQI), meaning their food safety will only continue to strengthen in time. Catsmo has added a fully dedicated sanitation team for post-production. They dedicate 200 hours a week to clean and sanitize the entire production site.

Fred Pothier, Chief Financial Officer of Catsmo Artisan Smokehouse, says that “without MTEC our success would not be possible.” They have been a vital part of changing the culture at Catsmo to become focused on reducing waste and optimizing their processes. He added that “MTEC brought us to the standard we were looking for and pushed us to get the best score possible.” Catsmo could have potentially lost $2,500,000 in sales, but through MTEC’s dedicated support they were able to obtain the resources they needed to thrive. When a problem lands on Fred’s desk and he is searching for a solution, the MTEC team is the first place he turns to. He knows that they will efficiently find him the answers he needs and see the problem through to the end.

MTEC takes great pride in serving companies of all backgrounds in the Hudson Valley and helping them realize their potential while reaching new heights. If you need help assessing your operations and improving your manufacturing processes, please call our Director of Operations, Phyllis Levine, at (845)391-8214 Ext. 3001 or via email to phyllis.levine@hvtdc.org to set up a complimentary visit.