Supply chains are constantly evolving, with new innovative trends emerging each year. As we near the end of 2023, it is crucial to stop and reflect on the past few year’s developments in supply chain management. Keeping up with the latest trends and technologies ensure businesses stay ahead of the curve and remain competitive in today’s ever-changing business landscape.

What are Supply Chains?

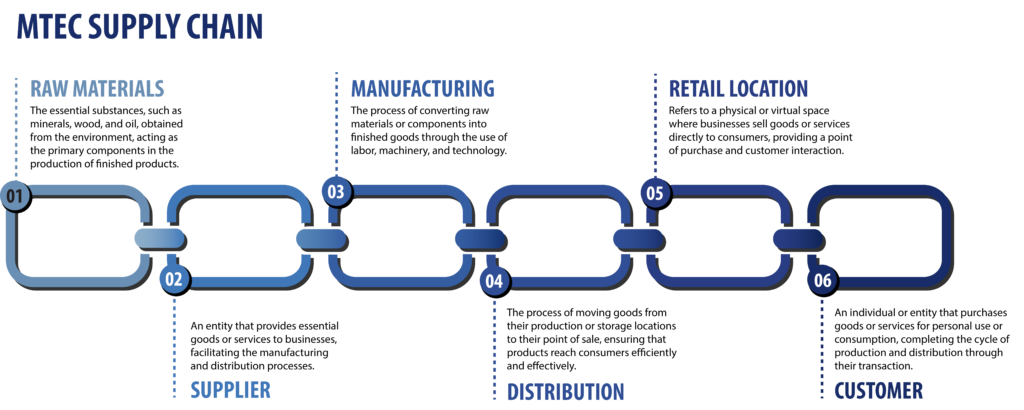

Supply chains remain a fundamental aspect of business operations, encompassing all the stages involved in getting a product from its raw material state to the hands of the customer. In previous blogs, we’ve discussed the fundamentals of supply chains. While most of the basics have remained the same, so much has changed regarding how modern supply chains operate. In order to understand the supply chains of today, one must understand the flow of materials within them.

Different stages within the supply chain are often divided into two categories: upstream and downstream. According to the current definition, upstream refers to the flow of materials into an organization, while downstream refers to the flow of products out of the organization and to the customer. Logistics is a key aspect of a business’s supply chain, and inbound logistics are associated with upstream activities such as receiving materials, storing them, and manufacturing processes. On the other hand, outbound logistics are related to downstream operations, including the movement of finished goods to customers. It’s worth noting that while these definitions remain generally consistent, some variations may exist depending on industry or context.

In today’s climate, it is important to understand the differences between procurement and sourcing in supply chain management. While these terms are often used interchangeably, they actually refer to distinct responsibilities within the overall supply chain process.

Sourcing, for example, is a critical part of the procurement process, but it specifically involves locating and evaluating various suppliers for products. This includes research and negotiation, as businesses look to optimize their costs while maintaining quality standards. On the other hand, procurement encompasses both sourcing and additional responsibilities, such as developing quality standards for materials and ensuring that the correct quantities are purchased in a timely manner. These elements work together to maintain the proper flow of materials throughout the supply chain.

Why is Supply Chain Management Important?

In 2023, supply chain management remains a critical component of business success, particularly as companies navigate an increasingly complex and dynamic global marketplace. Effective supply chain management enables businesses to optimize their operations, reduce costs, improve delivery times, and enhance customer satisfaction. As new technologies and trends emerge, supply chain managers will need to stay agile and adaptable in order to maintain a competitive edge

According to Steven Melnyk, Professor of Supply Chain Management at MSU, “Existing supply chain models have been very efficient at driving down costs. But the pandemic has highlighted serious risks to the supply chain, and now is the time for companies to take a serious look at whether they can simply return to their previous supply chain model”. He argues, “This will still include a global factor, but the long-term rebalancing will limit exposure by avoiding single-region or single-supplier sourcing. A balance of global, regional and local sourcing will prove to be less risky and more efficient in the long run.”

The Future of Supply Chains

According to a report by The Wall Street Journal, the COVID-19 pandemic has caused significant disruptions to global supply chains and is driving a shift towards more resilient and sustainable practices. Experts suggest that this shift is likely to bring about long-lasting changes in how companies manage the flow of goods, from raw material sourcing to manufacturing and distribution. The adoption of new technologies such as automation and nearshoring (transferring business operations to a nearby country rather than offshoring), as well as increased supplier diversification and a focus on sustainability, are among the key strategies being implemented by businesses to improve the resilience of their supply chains. A recent study found that businesses are recognizing the importance of flexibility in their supply chain operations, with a focus on risk management becoming an increasingly critical component of their overall strategy.

According to insights from industry experts, the post-pandemic era is witnessing a restructuring of supply chains with a renewed emphasis on regionalization. Companies are also adopting a new approach towards supplier management, diversifying their sourcing bases across different regions, rather than relying on single sources. Furthermore, supply chain automation is being implemented across various processes, ranging from warehouse operations to procurement decisions. These changes are all part of a larger effort to enhance the resilience of supply chains and prepare them for any future disruptions.

Now more than ever, agility is a defining characteristic of successful supply chain management. The pandemic accelerated trends within the supply chain and made it exponentially more important to ensure your supply chain is highly adaptable. Geopolitical pressures have caused many experts to question the stability of international trade routes. With this in mind, having domestic suppliers is essential when considering diversifying your supply chain. Just like in recent years, access to materials will continue to be limited. This further supports that the dexterity of your supply chain is a major determinant of your success.

At MTEC, we understand the importance of staying ahead of the curve when it comes to supply chain management. Our team of experts specializes in examining the efficiency of your supply chain, identifying areas of opportunity, and developing recommendations for improvement. By partnering with us, your business can reduce costs, increase efficiency, and achieve high standards of quality and service to stay competitive in the rapidly evolving supply chain landscape of today.

If you are interested in taking a closer look at your supply chain, or have questions regarding our services, contact our please call our Director of Operations, Phyllis Levine, at (845)391-8214 Ext. 3001 or via email to phyllis.levine@hvtdc.org.