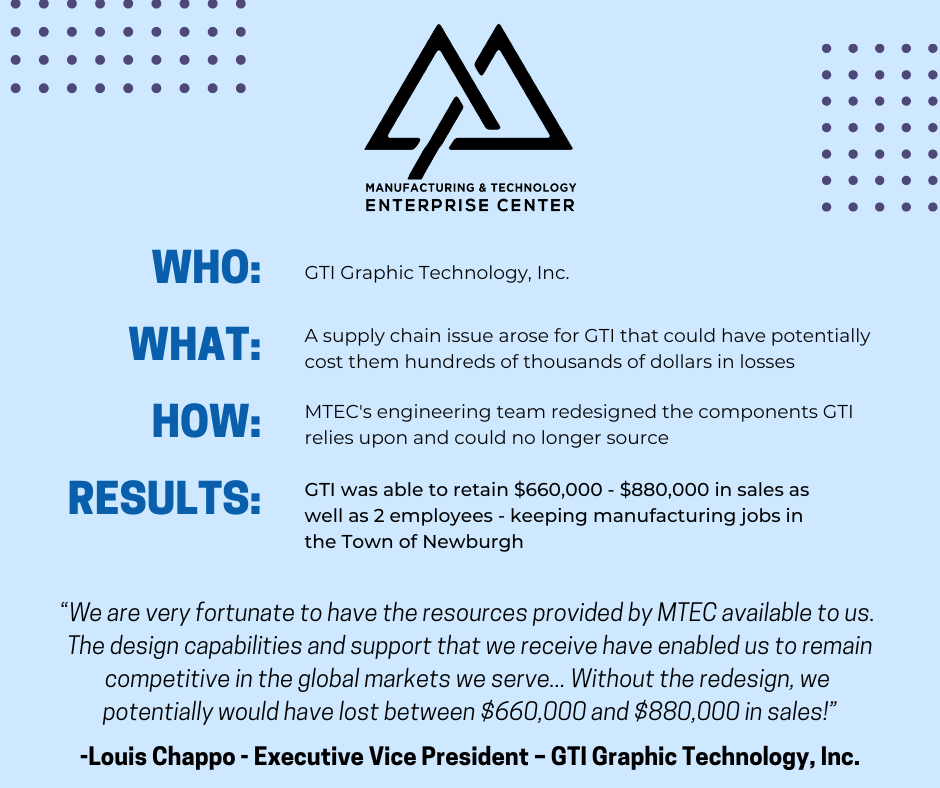

The past few years have been some of the most demanding and burdensome for all stages of the supply chain. As Director of Engineering at Manufacturing & Technology Enterprise Center (MTEC), Bob Incerto said, “in the current environment of supply chain constraints, component lead times are now measured in years as opposed to weeks or days.” This makes MTEC and GTI Graphic Technology, Inc.’s latest victory all the more sweet.

Graphic Technology, Inc. (GTI) is a leading supplier of tight tolerance lighting systems and services for critical color viewing, color communication, and color matching assessment. These systems are mainly utilized by the graphic arts and photography industries to mimic the lighting in retail environments, which allows designers to select the perfect shade or hue for their work. Due to recent supply chain issues, the controller boards (or PCBs) used in many of their lighting products have been unavailable. With a factory lead time of almost a year, GTI would have been poised to lose potentially hundreds of thousands of dollars in revenue.

MTEC has been working closely with GTI on the design, manufacturing, and programming of the controller boards used in many of their lighting products for several years and is a mainstay of their production. When this obstacle arose, MTEC’s engineering department was in a unique position to help. Our team of skilled engineers and interns redesigned the PCBs, secured a supplier for the redesigned PCBs, manufactured supporting components, and assembled and programmed over 100 boards to date. Since we continuously support the implementation and application as the finished boards are installed in units at GTI, MTEC was able to serve as an extension of GTI’s team to aid them through this hardship.

Our engineering team was able to extensively research comparable components to replace the existing ones and redesign the boards to fit these new components. Regarding the combined efforts of the two companies, Executive Vice President of GTI, Louis Chappo, stated, “We are very fortunate to have the resources provided by MTEC available to us. The design capabilities and support that we have received enabled us to remain competitive in the global markets we serve. Without the redesign, we potentially would have lost between $660,000 and $880,000 in sales!” In addition to retaining sales dollars, GTI was also able to retain two employees – keeping manufacturing jobs in the Town of Newburgh. We are proud to have aided GTI in their time of need.